Features and Technologies

Barry Allred was the developer of the single, double, and triple bubble tubes allowing for great increase on the volume of gas which can be excited by either RF or high voltage units. It is my opinion that the bubble may not be as important in a High voltage system as it is in the Bare-Rife environment. The great thing about having such a good group of “glass guys” is they are pretty receptive to our needs, wants, and desires and are generally quite helpful and instrumental in assisting with new designs.

Glass Type

[need content for glass types]

Getters

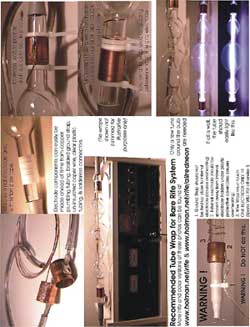

The “Getter” is standard issue on all tubes I use, regardless of configuration, to absorb impurities that leach from the glass over time which would cause a degeneration in tube performance. While the tube system provides continuous self cleaning in the high voltage circuits .... in the Bare-Rife environment, it need only occasionally be excited with a large neon transformer clipped to the ends to bring the gas back into pristine, like “new” condition.

|

| Internal Electrode and

Getter Exposed by Removing Protective Cap |

| Shown here is a Triple Bubble Bare-Rife tube being “reconditioned” by activating/heating the internal getters to absorb any impurities which have leached through the glass to contaminate the internal gas. |

|

[Add photo of circa mid /late 90s first experimental bubble tubes in series.]

While the single tube shown above is of current manufacture, the two tubes shown immediately following, are some of the very original bubble tubes made and contained internal getters. At that time, wraps and external electrodes were not well developed and arching, heating, etc was a problem. These tubes have seen some serious “abuse” whereas carbon arching is still evident and permanently embedded in the glass yet these tubes still maintain as pristine a “line” and color as they ever did.

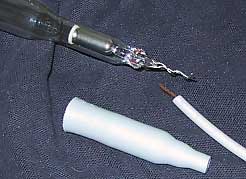

Protective Cap

The

protective vinyl end caps which encompass and protect the

internal electrodes are also standard issue and assist in

easier mounting. In the high voltage (EMEM-type) devices these

make clean entry points to securely hold your cable and provide

necessary strain relief.

The

protective vinyl end caps which encompass and protect the

internal electrodes are also standard issue and assist in

easier mounting. In the high voltage (EMEM-type) devices these

make clean entry points to securely hold your cable and provide

necessary strain relief.

Internal Pressures

Barry has developed a technique for safely allowing much higher pressures of 16 torr and better than the often typical 6-8 torr rating of most other tubes. Although some say it might be a bit harder to light, it allows for a very tight and concentrated beam the full length of the tube. Many have emphasized that this “concentrated” beam appears to maximize the radiant effect we most desire.

Standard Gases

[Need good complete list]

E-Gas and Other Proprietarty Mixes:

E-Gas is the signature mixture ... the sort of “secret sauce” of Rife plasma gas mixtures. This mixture has been developed over many years in conjunction with Rife builders, feedback and responses. If you are running any of the high voltage type devices (EMEM-type) this is an exceptional “performance GAS” and currently my preferred favorite for this environment.

Please Note: this mixture cannot currently be used on typical

high power Bare-Rife units. (The exceptional reactivity causes

it to run far to hot in that environment although this is

being closely examined as a possibility for low power Bare-rife

units which do not incorporate a linear amplifier or do not

run exceptionally high current.)

Wiring

Wiring to the tubes is a exceptionally important issue in BOTH environments from both a logistics and a safety perspective.

High Voltage Systems

Multi-stranded metallic high voltage wiring is absolutely necessary for a safe and reliable system. Standard high voltage wiring available at most neon sign shops (usually available form the same place you get the tubes) is great. Solid conductor, (not carbon filament), automotive ignition wire may be a useable alternative.

Bare Rife Systems

You have a bit more leeway here but need typically to be very large and have as MANY strands as possible. Additionally resonant length and routing become important considerations for tube connection. This will be covered in more detail via pictorial example and discussion elsewhere in these documents.

Tube Wrapping

A recommended proven method for wrapping tubes for a Bare-Rife environment is provided here for your convienience.